The methods and systems in ENERLEV which enforce the quality of the lighting fixtures

High level lighting products guarantee consistency, uniformity and high lighting quality. This is the importance reason of using uniform LED components that have gone through the BINNING process. The BINNING process refers to the classification and sorting of LEDs based on their optical and electrical characteristics. The process usually includes sorting LEDs with similar properties into bins (hence the name BINNING). Acceptable working methods in the industry make sure that the LED components classified together meet specific and appropriate needs, such as reference to the light temperature, the level of brightness, the accuracy of the colors they display, and more.

ENERLEV Group uses various methods to increase energy efficiency and reduce light pollution and uses LED components with extremely high light efficiency and a long life span that have undergone the strict BINNING process. Therefore, the lighting fixtures are classified as high-quality, consistent lighting products with top-notch performance in the field. The quality of the LED components is reflected:

- in the brightness and light output which ensures consistency in the light flux levels and increasing the energy efficiency of the product, which enables significant economic savings

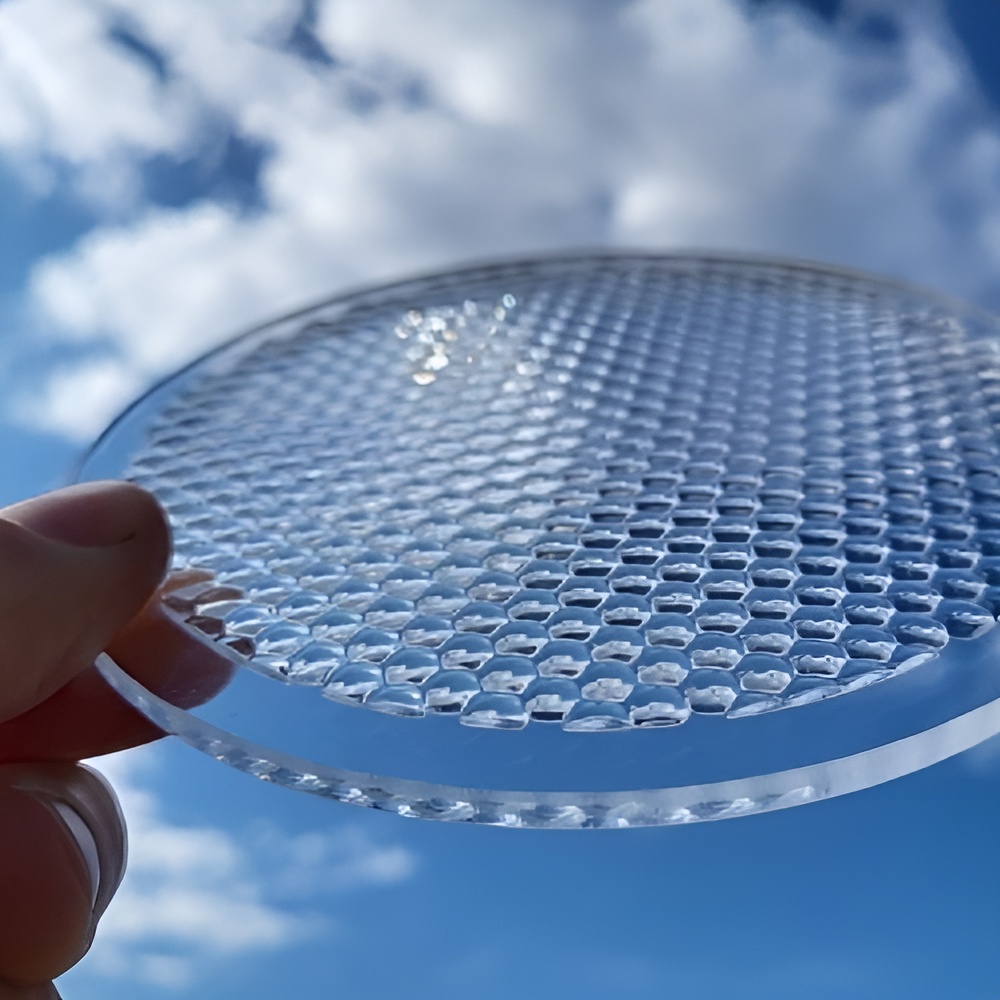

- In uniform light shade CCT with high accuracy of CRI colors, which makes the product safer. In addition, the use of a large variety of optical lenses and reflectors that prevent light pollution, which makes the product more ecological.

In order to ensure the uniformity of the assembly of the LED components and compliance with strict quality standards, Enerlev manufactures the LED modules in a mass automatic assembly line, which consists of unique equipment that works in coordination in order to optimize the production process, increase productivity, prevent unnecessary risk of human error and consistently guarantee the same quality every time the products. The SCREEN PRINTING machine, for example, is designed to apply tin paste while the PICK & PLACE machine places the LED components, the flow oven creates secure electrical connections between the components and the TESTING machine uses software and detection cameras to ensure that the product is of high quality and without defects that damaged the quality of the product during assembly.

Enerlev Article’s

enerlevgroup@gmail.com